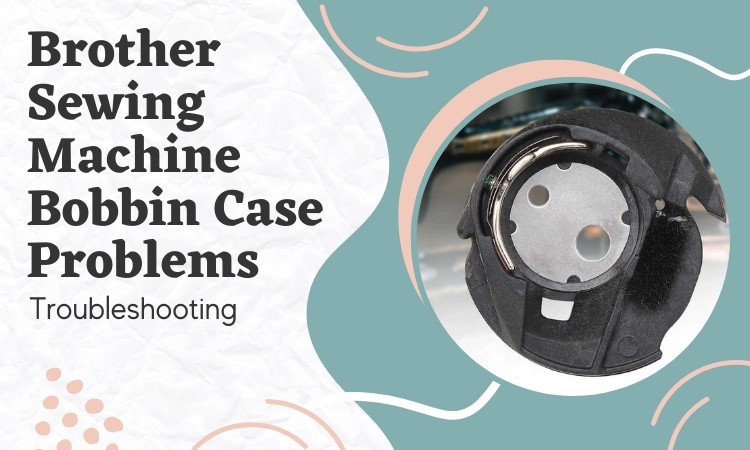

Brother Sewing Machine Bobbin Case Problems: Troubleshooting

Brother sewing machines are very well known for their good quality. However, the users can encounter some problems once in a while. Especially with the bobbin case as it wears out due to constant moving over time.

So, here we talk about the common brother sewing machine bobbin case problem.

The common problems with brother sewing machine bobbin case includes jamming, bobbin case not turning, bobbin case stuck etc. In most cases, bobbin thread winding up is the main reason why this happens. If the bobbin case is inserted incorrectly, or you are not using the right bobbin, such problems may arise.

Now that we’ve discussed the type of problems, let’s get into the solutions!

Solutions to 4 Common Brother Sewing Machine Bobbin Case Problems

Here are the most common brother sewing machine bobbin case problems at a glance-

| Problem | Reason | Solution |

| Bobbin case not turning | bobbin tension way too tight bobbin thread winding up | Loosen the bobbin tension Replace the needle |

| Jamming in the Bobbin Case Area | Not threading the upper thread or needle thread correctly Not wound the bobbin thread evenly Not using the correct size of bobbin Inserting the bobbin case incorrectly. | thread the upper and needle thread correctly Wound the bobbin thread evenly Use correct size of bobbin Insert the bobbin case correctly |

| Bobbin case stuck in the sewing machine | Not inserting bobbin case properly | Insert the Bobbin case correctly |

| Bobbin case jumping | Not using right bobbin. Not installing the bobbin case correctly Not wounding the thread correctly on the bobbin Scratched or burred bobbin case | Use the correct bobbin Clean the bobbin case Recheck the bobbin |

Problem 1: Brother Sewing Machine Bobbin Case Not Turning

One of the most common issues of brother sewing machine bobbin cases is the case not turning. It means that the case can’t move the hand wheel or the thread causing it to jam.

Reasons:

One reason why the bobbin case won’t turn might be that the bobbin tension is way too tight. When the machine gets jammed the bobbin tension gets tighter and, as a result, the bobbin case stops turning. It can also cause timing issues of the machine.

Another reason might be that the bobbin thread winding up. It can happen due to the uneven bobbin tension throughout the case.

Solution:

Fixing this problem isn’t that complicated. Generally, loosening the tension in the case and replacing the bobbin gets the job done. The steps are –

Loosen the Tension:

When the tension becomes too tight the bobbin case does not turn. To fix this, just move the dial settings to a lower number. It will loosen the needle thread tension of the machine.

Now recheck to ensure that your bobbin is turning again. If it doesn’t, try lowering the tension a bit more. However, if it doesn’t work at all, you need to replace the bobbin.

Replace the Old Bobbin:

Get a new bobbin and wind the thread slowly and carefully. It will ensure the tension is even. Next, replace your old bobbin with a new one. After fitting it properly, resume sewing again.

However, if it still doesn’t work, something might be jammed in the bobbin. Keep reading to learn how to solve it!

Problem 2: Jamming in the Bobbin Case Area

Bobbin case jamming is another common problem that the users struggle with. Here are reasons and solutions.

Reasons:

Here are a few reasons why the sewing machine gets jammed in the bobbin case area.

Not threading the upper thread or needle thread correctly can be one of the reasons for jamming. Also when you fail to wound the bobbin thread evenly on the bobbin, it can also cause the machine to jam.

Other common reasons include not using the correct size of bobbin, and inserting the bobbin case incorrectly.

Solution:

The steps to solving a jammed bobbin include-

- First of all, thread the upper and needle thread correctly.

- Next, go ahead and make sure that the bobbin has the bobbin thread wound evenly around it. Also, ensure that the bobbin thread goes straight through the bobbin thread while you wind your bobbin.

- If your bobbin is the wrong size, replace it with the correct size of bobbin. That needle should be around 11.5 mm or 7/16 inch in height. For clarification, check the manual for your machine.

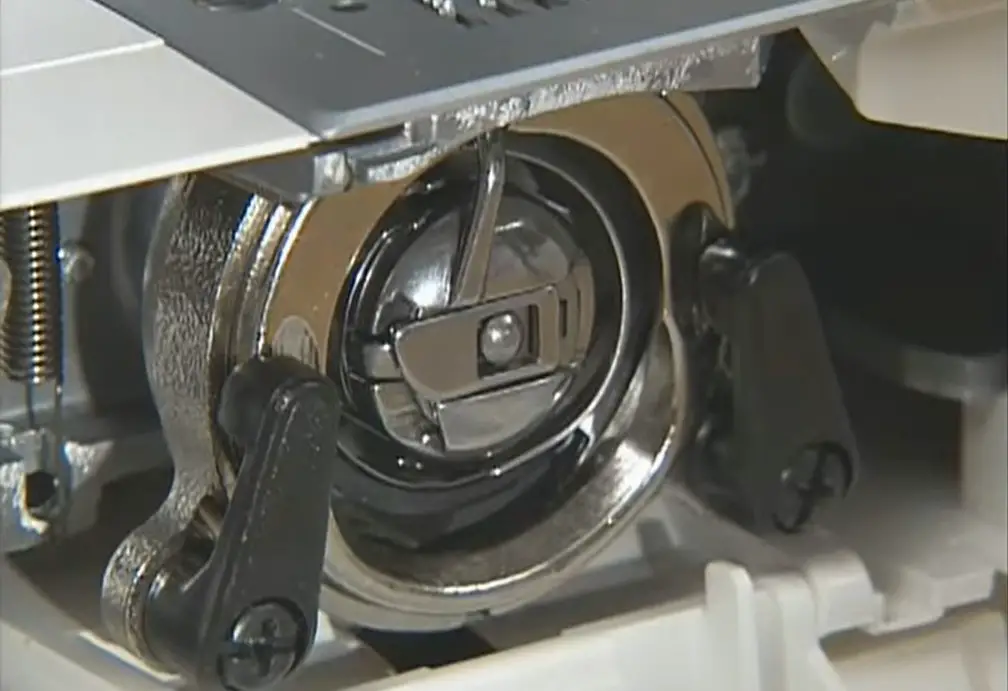

- The problem could also arise if you had inserted the bobbin case incorrectly. Remove the case, and insert it accordingly. Make sure the triangle make over the case aligns with the circle mark on the machine.

- Once you have inserted the bobbin correctly, remember to keep the bobbin thread behind the spring of the bobbin case. Once you are done with everything, you may start sewing now.

Problem 3: Bobbin Case Stuck in Sewing Machine

Often the Bobbin case gets stuck inside the sewing machine. As a result you can move the needle or run the thread as well.

Reasons:

The reason why it happens is because the bobbin case is inserted in the wrong way which causes it to get stuck. Also thread can get caught on the shuttle hook.

You need to insert it correctly following the steps given in the solution part to get it fixed.

Solution:

Here are the steps to follow if your bobbin case is stuck-

- Start by turning the sewing machine off

- Raise the needle to the highest position and then remove it.

- Now, discard the presser foot and presser foot holder.

- Discard the needle plate cover, as well.

- Now with the round-shaped screwdriver loosen the 2 screws you will find on the needle plates.

- Finally, take the bobbin first and then remove the bobbin case.

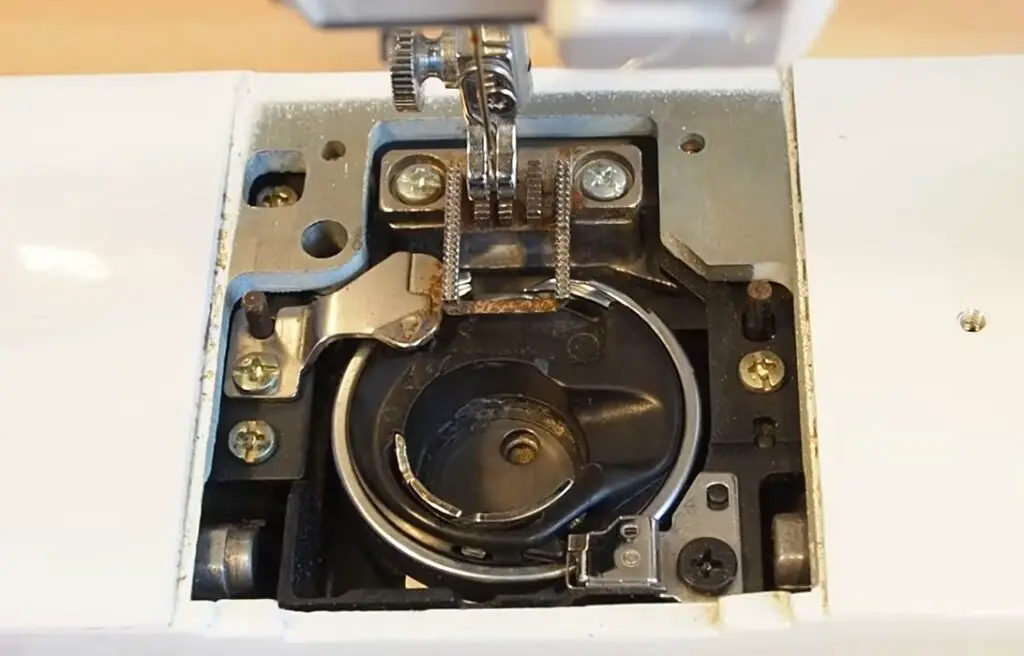

- You can clean the bobbin case off with a lint brush if you want. This step is totally optional.

- Now you will have to re-insert the bobbin case. Make sure you do it correctly and the triangle and circle marks align with each other.

Now you can resume sewing again and hopefully the issue will be solved.

Problem 4: Bobbin Case Jumping

You may notice the bobbin case coming out of his position or or keeps jumping whenever you try to run the needle. If not fixed as soon as possible, there are chances the thread will get tangled and make a mess.

Reason:

Here I have listed down a number of reasons for this problem.

Not using the correct bobbin will lead to bobbin case jumping. Because as a result the thread won’t be threaded correctly which will cause the issue.

If the bobbin has not been installed in the bobbin case correctly the issue will arise, as well. This issue is also very frequent in Brother SC9500 model.

Solution:

Follow these steps well to fix the problem of bobbin case jumping.

Clean the Bobbin Case:

Turning the power switch off, take out the bobbin case from the sewing machine. Check out the instructions manual provided with the sewing machine for this.

With the help of a brush or vacuum cleaner wipe off any dust or lint from the bobbin case and the outer rotary hook area.

Insert the Bobbin Case Properly:

Now after you are done with the cleaning it’s time to insert the bobbin case properly. Insert it in a way that aligns the triangle mark and the circle marks on the bobbin case and the machine.

The proper alignment will ensure that you have successfully inserted the bobbin case.

Check the Bobbin:

Now it’s time to inspect your bobbin.

- Grabbing the both sides of the needle plate cover, slide it all the way to the machine front. It will remove the cover along with the bobbin.

- Ensure that the bobbin you are using is the ideal one or the right size for the machine.

- You need to also ensure that you have the thread properly on the bobbin.

- Finally, recheck whether the bobbin has been properly inserted. Re-install it if necessary.

Frequently Asked Questions (FAQs):

Why is My Brother machine not catching the bobbin?

One reason for this is that the upper needle thread tension might be way too tight. Also, if the thread is caught on something between the needles it can happen. As the bobbin thread becomes too tight to be picked up by the needle.

How do I reset the bobbin tension?

You can reset the bobbin tension by turning the little screw you will see over the bobbin case. To tighten the tension, turn the screw clockwise. And to loosen the tension, move it counter-clockwise.

How do you check bobbin tension?

To check the bobbin tension, take out the bobbin from your machine first. Now holding the edge of your bobbin thread, pull on the thread. The thread is supposed to unwind just a bit and the bobbin case will drop 1 to 2 inches. If they do, the bobbin thread tension is correct.

Wrapping Up

Hope you now have the basic idea on how you can fix the brother sewing machine bobbin case problem. You know all the reasons and how to fix them now!

Clean the bobbin case regularly along with the other parts of the machine. It will ensure that you face lesser issues.

That is all as of now. Have a great day ahead!