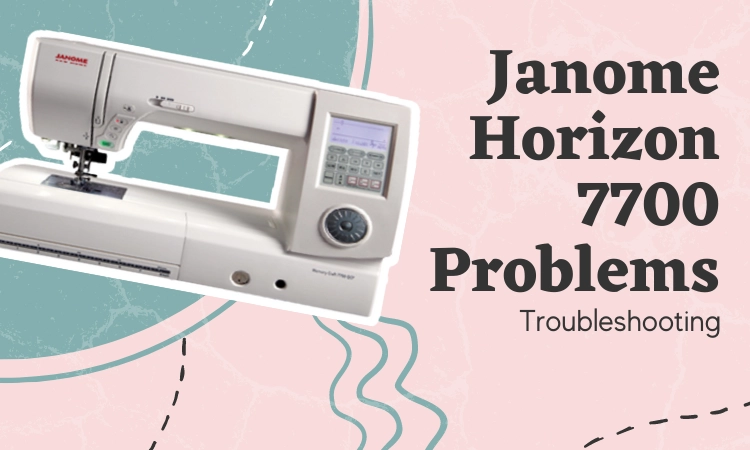

Janome Horizon 7700 Problems: Troubleshooting

Janome Horizon 7700 is very popular due to its high-end sewing functions. However, along with all the advantages, there are ceratin problems as well.

So, what are the common janome horizon 7700 problems?

The most common problems with Janome horizon 7700 include seam puckering, buttonhole not sewing properly, needle breaking etc. In most cases, incorrect needle threading is the main reason for this. If there is incorrect stitch density, defective bobbin or lint buildup, such a problem may arise.

While these are the basics, each problem can be solved with a bit of effort. Let’s begin!

Solutions to 4 Common Janome Horizon 7700 Problems

Here I have listed down the common problems of janome horizon 7700. Have a look.

| Problem | Reason | Solution |

| Buttonhole sewing is not sewn properly | Incorrect stitch density Not using interfacing for the stretch Not lowering buttonhole lever | press on the “+” “-” sign on stitch length adjusting key to adjust stitch density Use interface Lower button-hole lever |

| Bobbin thread breaks | Bobbin thread is not threaded properly Lint/ dust buildup inside the bobbin holder Faulty Bobbin case The bobbin is defective | Thread the machine properly Clean the bobbin holder Replace the bobbin |

| Seam puckering | Too tight needle thread tension using too heavy needle Too long stitch length Not adjusting the foot pressure properly Not using a stabilizer | Adjust the thread tension Use right size of needle Make your stitches a bit shorter to avoid seams puckering Apply an stabilizer. |

| Needle breaks | Clamp screw loose Wrong type of needle Inappropriate pressure foot | Tighten the clamp screw Replace the needle Use the right needle size Put the right pressure foot while sewing |

With the basics discussed, let’s dive deep into it!

Problem 1: Buttonhole Sewing Is Not Sewn Correctly

After sewing the buttonhole, you often notice it has not been sewn properly. The stitches simply don’t look right giving it a misaligned look.

Reasons:

Let’s first go through the reasons for why it happens before we move towards the solutions.

- Incorrect stitch density for the specific fabric you are sewing

- You have failed to use interfacing for the stretch or synthetic fabric

- You have not lowered the buttonhole lever.

Solution:

If you encounter problems with buttonhole stitches, try these easy fixes.

Adjusting the buttonhole stitch density:

- To adjust the buttonhole stitch density to your requirements, simply press on the stitch length adjusting key.

- You should notice a “+” sign there. Press on it if you want the buttonhole stitches to be less dense.

- Similarly, by pressing “–” sign on the adjusting key, you can make those buttonhole stitches denser.

After you are done adjusting the buttonhole stitch density, make sure to apply an interfacing. Also, lower the lever as down as it will go.

And just like that you will fix your buttonhole sewing problem.

Problem 2: Bobbin Thread Breaks

Thread repeatedly snapping or fraying from the needle is a common janome horizon 7700 issues. Luckily there are some easy ways to fix it.

Reasons:

I have listed some possible reasons why it happens.

- One reason is failing to thread your bobbin thread properly.

- Also, if there is any lint buildup inside the narrow paths of the bobbin holder, the bobbin thread will break.

- Another reason may be that the bobbin you are using is defective.

Solution:

In order to solve a bobbin thread breaking, you need to insert it properly and make sure it’s clean.

Inserting the Bobbin Thread Properly:

If your bobbin thread has not been threaded properly, then have a look.

- Start off by setting the bobbin inside the bobbin holder. The thread should run off counterclockwise, make sure of that.

- Next, guiding the thread inside the notch, pull it out to the left. Now insert the thread between the spring blades.

- Keep pulling the thread in hand till it glides within the side notch. The bobbin should be turned counterclockwise.

- Now slightly pull some of the thread to the edge. Keep the length about 4 inches.

- Then finally, after reattaching your hook cover plate, you should be done.

Cleaning the Bobbin Holder:

Cleaning the lint off sewing machine is another fix for this issue.

- Start by turning off the power button.

- Then take out the needle and the presser foot. Discard the screws and needle plate as well.

- Now lift up the bobbin holder and take out the bobbin carefully. Don’t use too much force.

- Using a lint brush, clean every nook and cranny of the bobbin holder thoroughly.

- Now head towards the feed dog and clean it. If possible, clean the auto thread cutter as well.

After performing these steps successfully, the bobbin thread should not break again.

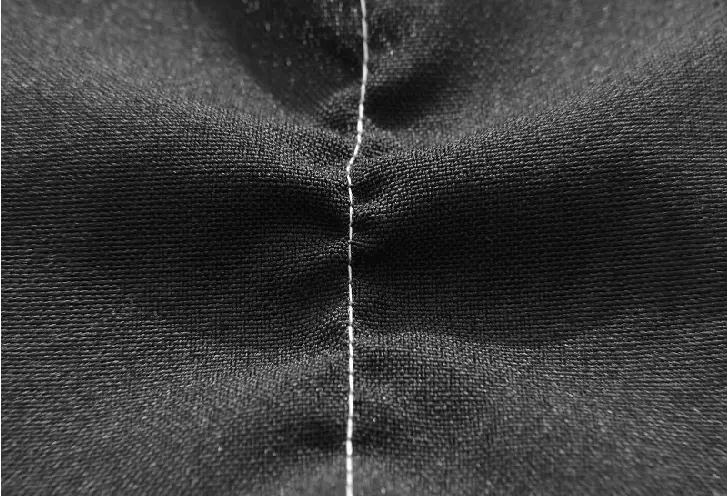

Problem 3: Seam Puckering

While Sewing you may have noticed the same pukuring and the stitches look loop-ey. The seams look poorly finished and do not look good at all.

Reasons:

Here is a list of possible reasons on why it happens.

- Seams pucker when the needle thread tension becomes way too tight.

- If you use a needle that is too heavy for your project fabric, the seams remain puckered

- If stitch length happens to be too long this issue arises. Not only this but also the thread gets caught in the machine very frequently.

- Not adjusting the foot pressure properly

- Not using a stabilizer while stitching very fine fabric.

Solution:

Follow all the steps to avoid seams puckering on your fabric.

- To adjust the thread tension, set the tension dial a number low.

- Now, look into the instruction manual for the right size of needle for a certain fabric and use that.

- Try to make your stitches a bit shorter to avoid seams puckering

- Apply a stabilizer especially when you are working on a fabric with a very fine texture.

After you have followed all this steps try Sewing the fabric again. And your janome horizon 7700 seam puckering issue should be solved

Problem 4: Janome Horizon 7700 Needle Breaks

If you are facing the issue of needles repeatedly snapping while sewing, don’t worry. Here I have shown steps on how to fix janome 7700 needle breaking problem. This problem is very frequent in Janome HD1000 and HD3000 as well.

Reasons:

One reason for why your needle breaks can be that the clamp screw is loose. A loose clamp screw makes the needle fall down, get caught in the bobbin area and finally break.

If you are using the wrong type of needle that is not suitable for the fabric, it can be the cause. Also, using inappropriate pressure can also be the reason behind the needle breaking

Solution:

Follow these easy steps to stop your needles from breaking anymore.

- First of all, you need to securely tighten the needle clamp screw. Tighten it firmly all the way to prevent the needle snapping.

- Next, check what type and size of needle you are using and where it is suitable for the fabric. Read the instruction manual and make sure to match the texture and type of material you will be working on.

- While stitching, make sure that the feed dogs are moving that fabric underneath the needle. Resting your hand on the cloth, guide the stitches to the right direction. Do not apply extra pulling and pushing. It will save your needle from snapping in half.

Also always remember to use the right pressure foot while sewing, this will prevent you from putting extra pressure on the needle and breaking.

Frequently Asked Questions (FAQs):

Why is my Janome sewing machine not stitching?

There can be several reasons for why the Janome machine is not stitching. For example, tangled thread, not feeding the fabric evenly etc. Also, if there is any lint or dust build up inside any part of the machine, the needle stops moving and it leads to the machine not stitching.

Why is my Janome bobbin not winding evenly?

The thread not being properly wrapped around the tension disc is the reason why it’s not winding. To fix this, you need to pull the thread through the tension discs properly. Pull it through the thread guides as well. Do it all before you start winding and the bobbin should wind evenly

Why is my sewing machine not picking up the bottom thread?

If you hold the needle thread way too tightly while sewing, it won’t pick up the bottom thread. Always hold the thread gently so the end does not go down inside the shuttle. It can also happen if your thread is incorrectly threaded.

Wrapping Up

That was everything on the janome horizon 7700 problems. With all the information provided, you now will be able to fix your sewing machine quickly!

Always make sure you have wound the threads properly, before you start sewing. Also keep the machine clean. That way, you will face these problems less often.

That was it. Happy sewing!