How to Sew Ripstop Nylon Fabric Correctly – Follow This Way

Ripstop fabric is a special category of materials of different compositions, reinforced with a reinforcing thread. Its other names are “coated ripstop”, “ripstop scrap fabric”, and “rip-stop lightweight fabric also”.

Outwardly, such a canvas has a textured pattern with small squares, which adds extreme strength and some decorative effect. The thread, as if creating a frame, can be made of nylon or other fiber.

It is woven into the base every 5-8 mm and prevents further rupture.

The development of the fabric was commissioned by NATO for military uniforms, which fully explains the seriousness of its operational and protective properties.

Characteristics of ripstop fabrics

Any natural or synthetic fiber is used as the main thread. Accordingly, the properties of such tissues and ripstop nylon scrap fabric pinking shears will be different.

But there are basic characteristics for all modifications:

- strength;

- no tendency to shrink;

- tightness;

- water resistance if the fabric is treated with PU impregnation;

- ease of care.

The disadvantages of the material are due to the composition.

For example, a nylon base can be electrified, and with a high percentage of natural fibers and special processing, the price often “bites”.

Varieties of material

There are many types of ripstop fabric, which are different in texture, density and weight:

- Nylon ripstop (sew ripstop nylon fabrics) is a lightweight fabric with moisture-resistant properties, is not affected by fungus and insects, is easy to clean and dries quickly. The minus of the material is sensitivity to light and high temperature.

- Polyester ripstop is a heavier and shape-stable material, devoid of the disadvantages of nylon.

- Ballistic nylon: The basis consists of the polyamide fiber giving to a cloth sliding properties.

- Mixed ripstop: The base is small stitch length sewing ripstop nylon fabric or silk. The reinforcing thread has a complex structure of a polyester core in a cotton braid – it increases the hygroscopicity of the product.

Thanks to technological innovations, a material with special properties is obtained, which is very popular for special services clothing:

- Kevlar threads increase the tear resistance of the fabric;

- para-amide fiber, impregnation with Teflon or silicone give fire resistance;

- anti-static treatment reduces the tendency of the ripstop fabrics to accumulate static electricity.

Where are ripstop fabrics used?

Since strength and durability are the main advantage of this category of materials, regardless of the brand, they are used for products exposed to extreme influences and lightweight clothing with high protective properties:

- Overalls and uniforms for law enforcement and government agencies – usually suits and overalls are sewn from a blended fabric with cotton. For firefighters, the canvas is coated with Teflon or slippery silicone, for the military, a Kevlar thread is added.

- Tourist and sportswear, bags, accessories.

- Tents, awnings and covers protect well from wind and bad weather.

- Parachutes, sails for yachts, flags and banners – do not fade in the sun and staunchly resist atmospheric disasters.

Clothing made from this material is strong, durable, does not stretch and almost does not wrinkle.

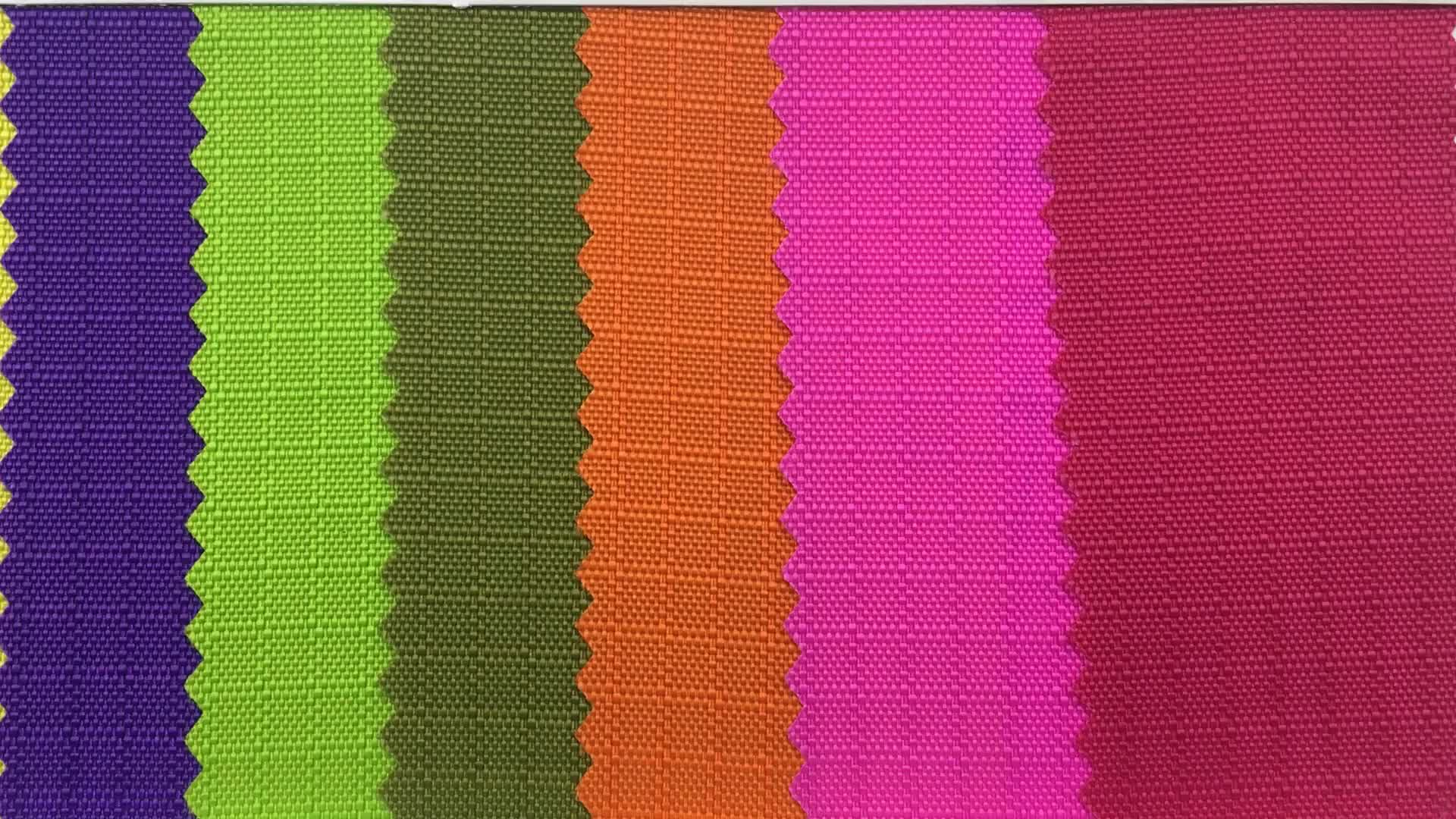

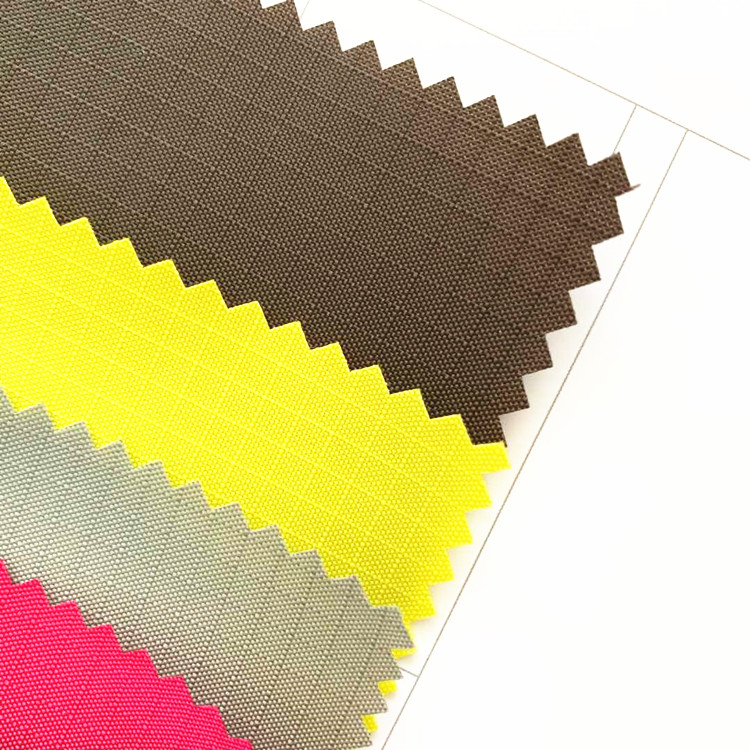

A huge palette of colors removes all restrictions in use.

Camouflage print, olive, green, bright colors are very popular – it all depends on who the item is intended for.

Special care instructions

Ripstop fabric products do not require special care, but it is still better to adhere to some wishes. For tent material, awnings and umbrellas, sometimes it is enough to dust off with a damp cloth or brush without washing.

With regard to haberdashery and clothing, we recommend that you consider the following:

- Wash by hand or in a washing machine at a temperature not exceeding 50 degrees, preferably without spinning.

- Bleaching and dry cleaning of the ripstop fabrics can be carried out, but without the use of trichlorethylene.

- Lay flat to dry out of direct sunlight.

- Ironing for and synthetics is not required. In other cases, you can give the product a look “from the needle” with a steam generator or iron – through wet gauze at the temperature indicated on the description in the label (depending on the composition of the fabric).

If small cuts or punctures have formed, you can repair the product with a special reinforced self-adhesive tape on one or both sides of seams of the fabrics from ripstop.

Depending on the scale of damage, a line is laid with nylon thread.

Durable and aesthetic rip-stop fabric has proven itself best in overalls and equipment.

The dense structure protects well from the wind, according to reviews it lasts up to 10 years and is resistant to damage.

Ripstop nylon fabric and its features

Ripstop Nylon is a synthetic fabric and woven in three dimensions to make it tear resistant.

It was developed during World War II as an alternative to silk for parachutes. Today, ripstop nylon is still used for parachutes, as well as boat sails, balloons, kites, flags, banners, and many other travel paraphernalia such as tents and sleeping bags.

Ripstop nylon is smooth and durable, and if you already know how to sew slowly, you already know most of what you need to know how to sew ripstop nylon fabric properly.

Sewing ripstop nylon fabric tight using a sewing machine

You can sew straight this fabric with a regular sewing machine, but since nylon ripstop is slippery, the walking presser foot or walking foot is a good accessory.

The walking leg and a presser foot moves the top layer of fabric while the machine moves the bottom layer. Your machine must be able to make straight and lightweight zigzag stitches per inch a presser foot or walking foot and move in reverse.

Hold the ripstop nylon seams by pulling the fabric on both sides of the needle instead of trying to pull the ripstop nylon fabric seams through. Never attach ripstop nylon.

Use glue to secure the seams.

Needles

American sewing machine needles come in sizes from #8, which is the lightest, to #19, which is the heaviest. Use a #12 or #14 nylon ripstop stitches. Don’t worry about putting too much of a hole seam needle through.

The single most important factor in sewing this fabric is to keep it tight and seam while sewing ripstop nylon. Also, remember that there can be a lot of stress on thin stitches. Because the seam fabric is stiff, you should never sew straight with a dull needle. Dull slippery and a seam needle stitches make a clicking sound as they penetrate the fabric.

A bent fraying right needle are worse than boring thin stitches, as they shed a lightweight stitch length.

Thread and cutting

Never use cotton thread to sew ripstop nylon.

Use commercial quality, 100% nylon or 100% polyester thread. Polyester is slightly softer than nylon. The diameter and weight of the fraying stitch thread depends on what you are sewing. The two standard woven edges sizing systems you are likely to come across are called denier and tex.

The latter expresses the various weights of a thread of 1000 meters in grams.

Denier instead weighs 9,000 meters of the edges.

Kite makers use a stitch that is 300 denier, or about 33 tex. The parachutes are stitched with a thread that is three times heavier. When sewing ripstop nylon, use about eight stitches per inch.

Ripstop edges wear out quickly unless they are hemmed or soldered. There are two ways to cut fabric.

The ripstop is usually cold cut with a sewing tool called a rotary cutter. Moreover, these cutters are used with a mat and ruler. Of course, any cold cut you make must be hemmed. Likewise, this fabric can also be hot cut with a wood-burning tool or a soldering iron.

The ripstop nylon must be cut into a large sheet of glass.

Never use plastics such as plexiglass instead of glass because the heating tool will fuse the fabric with the plastic.

Sewing ripstop nylon fabric and simple tips how to sew ripstop nylon?

Rip-stop has many advantages.

With all the many varieties, the material has common advantages:

- Strength. Even if a hole has formed on the canvas, it will not spread and will not increase in size. Use sharp scissors and a hot knife. A hot knife will be connected with hot air balloons, a glue stick, french seams, a seam allowance, reusable bags and a pin ripstop nylon fabric.

- Resistance to deformation and abrasion. Things do not wrinkle, do not shrink, do not stretch, do not become covered with spools.

- Water resistance. The ripstop does not let moisture through, after washing it dries very quickly.

- Frost resistance.

- Immunity to ultraviolet rays. The canvas, covered with a special impregnation, will not fade in the sun even after a few years.

- Fire resistance. Ripstop nylon is also not burned through due to special impregnation.

- Breathability. This quality applies mainly to clothes with a prevent fraying weave in the base.

- Resistant to dirt and chemicals.

- Not susceptible to the development of microorganisms and decay.

- Relative lightness and softness and sewing of ripstop nylon.

Application area to sew ripstop nylon fabric

Ripstop fabric is used to create products for the following areas of human activity:

- military;

- industrial;

- medical;

- sports;

- tourist;

- entertaining.

More dense and rigid types of this textile are in demand for the creation of special-purpose equipment, narrow-profile overalls.

Soft and light varieties are in use when sewing clothes and other things for household needs.

From the material produced:

- equipment and office uniforms for military personnel, employees of the Ministry of Emergency Situations, firefighters, medical staff, etc.;

- army and combat body armor, weapon cases and other similar protective coatings;

- sportswear, ski suits (shorts, pants, overalls, jackets);

- tourist equipment (tents, sleeping bags);

- any bags and backpacks;

- all kinds of canopies and awnings (tourist, commercial, domestic);

- cases for phones and other gadgets;

- sails for paragliders, kites, yachts, etc.;

- canvases for kites and balloons, parachutes;

- flags, banners;

- lambrequins, etc.

Production tricks of sewing ripstop nylon fabric and how to sew ripstop nylon?

A specific weaving process of crosshatch pattern weights makes the rip-stop so strong.

On it, the reinforcing threads cross the base at the same distance (within 5-8 mm).

Reinforcing fibers are larger in volume than carrier fibers.

Therefore, a checkered crosshatch pattern weight stands out on the finished canvas.

Comfort in wearing such products is provided by the ripstop seams braid that is pleasant to the touch, which is applied over reinforcing synthetics!

2 thoughts on “How to Sew Ripstop Nylon Fabric Correctly – Follow This Way”