Common Janome HD-3000 Problems You Better Know About!

The Janome HD-3000 is a popular sewing machine that offers advanced features and a durable metal construction. However, like any machine, it may experience problems that can hinder its performance.

So, what are some common Janome HD 3000 problems?

The most common Janome HD 3000 problems include the top stitch looping under the fabric, skipping stitches, only sewing in reverse, or not sewing in reverse at all. Other than that, the machine may get stuck in one stitch, bobbing winder slipping, needle getting stuck in the clamp, etc.

These common problems will be explored in this article, along with tips on avoiding or addressing them.

Janome HD-3000 Problems and How to Solve Them

Before we discuss the problems with the sewing machines, let’s take a quick look at the table for a glimpse. Note that, some problems may be similar to those of other Janome models, like the Janome 9400.

| Problems | Reasons | Solution |

| Top stitch is looping underneath the fabric | The tension of the needle thread is too loose | Tighten the tension of the needle thread |

| Skipping Stitches | 1. Incorrectly inserted, bent, or blunt needles. 2.Not using the proper needle or thread. 3.The needle thread not threaded properly. 4.Presser foot pressure not strong enough. | 1.Re-insert the needle. 2.Use the right type of needle and/or thread, 3.Re-thread the needle, adjust the foot pressure. |

| Won’t sew in reverse or only sews in reverse | Reverse button got stuck or not working | Fix the reverse button bar |

| Bobbin winder slipping | Broken winder spindle | Replace the winder spindle |

| Stuck in one stitch | The thread jammed inside the machine. | Perform thorough cleaning |

| Feed dogs not working | Feed dogs or its lever may be broken | Replace the damaged part |

| Top thread tangles around take up lever | 1.Wrong orientation of the thread spool, 2.Using incorrect needle or thread, 3.Incorrect tension of the thread, 4.Rough spots in the foot plate, 5.Dirty tension discs. | 1.Using a different spool of thread, 2.Turning the spool around, 3.Using the correct needle, 4.Loosen the thread tension, 5.Clean the foot plate and the tension disc. |

| Bobbin casing keeps popping up | Dirty bobbin holder | Clean the bobbin holder |

| Needle gets stuck in clamp | Faulty clamp | Replace the clamp |

| Getting loops underneath works | 1.Not using the correct needle size, 2.Threading is incorrect | 1.Use the correct needle size, 2.Rethread the needle. |

Let’s solve some Janome HD 3000 problems now that we have some basic ideas about them.

Problem One: Top Stitch Is Looping Underneath The Fabric

A common issue with the Janome HD3000 is with the tension. Sometimes, the top stitch may keep looping under the fabric.

Reason: Needle Thread Tension Is Too Loose

When the tension of the needle thread is too loose, the top stitch has a tendency to form a loop beneath the fabric.

Solution: Tighten The Tension of The Needle Thread

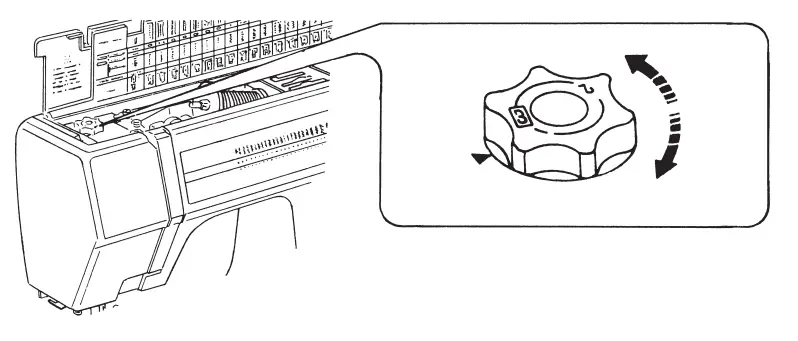

Tighten the tension of the needle thread if you encounter this problem. Set the dial to a larger number to tighten the tension of the needle thread. The standard number for tension is 4. However, Janome recommends from number 2 – 6 for standard stitches.

The needle thread and bobbin thread should be intertwined at the intersection of two strands of material when sewing straight seams.

Problem Two: Skipping Stitches

Another problem you might face using the Janome HD 3000 is that it may skip stitches.

Reasons:

- There is an incorrectly inserted needle, a blunt needle, or a bent needle.

- Both the needle and thread are unsuitable for the work.

- Threading the needle is incorrect.

- There is not enough pressure on the presser foot.

Solutions:

If the needle is incorrectly installed, bent, or blunt, then you will need to check and re-insert the needle. Here is the basic guideline:

- Lower the presser foot and turn the handwheel toward you to raise the needle.

- Then disconnect the power to the sewing machine.

- Turn the needle clamp screw from right to left. This will loosen it.

- Remove the needle from the clamp.

- Insert a new needle into the needle clamp with the flat side facing outward.

- Tighten the clamp screw firmly after pushing the needle into the clamp as far as it will go.

To check if you are using the right thread or needle for the right type of work, check the table below-

| Fabric Type | Needle | Thread |

| Fine (lawn, georgette, tricot) | #80-100 | #9/65-11/75 (blue tip) |

| Medium (sheeting, jersey, wool, knit) | #50-80 | #11/75-14/90 (red tip) |

| Heavyweight (denim, tweed, coating, quilting) | #30-50 | #14/90-16/100 |

There are differences between different threads. For example, v69 and v92 threads have different applications.

If you suspect your needle thread was not threaded properly, here’s how you do it-

- Raise the take-up lever to its highest position by turning the handwheel toward you.

- The presser foot lifter is used to raise the presser foot.

- Pass the thread through the thread guide after it is wound onto the spool. Follow the slot on the right and draw it down.

- To thread the machine, guide the thread underneath the thread guide plate starting from the right side and guide it towards the left. Then, pull the thread upwards towards the needle.

- Over the take-up lever, draw the thread firmly from right to left until the thread reaches the eye of the take-up lever.

- Once it is in the slot on the left, guide it down.

- The thread should be slid to the left of the needle bar thread guide from behind the needle bar.

- Get the needle threaded.

You may not have the pressure dial correctly set on your presser foot if that’s not the problem. When sewing regular fabrics, set the machine to “3.” For appliques, set it to “2.” If sewing delicate fabrics such as chiffon, lace, and organdy, adjust the pressure to “1.”

Problem Three: Won’t Sew in Reverse or Only Sews in Reverse

One of the most common problems that users face is that the machine either sews in reverse or only in forward.

Reason: Malfunctioning Reverse Button

The reverse button may get stuck or malfunction, which prevents sewing in reverse or only causes sewing in reverse.

Solution: Fix the Reverse Button Bar

- Remove the sewing machine’s base plate.

- Push the reverse button to find the the bar that moves.

- The bar should be connected to a spring. If it’s not, reconnect the bar with the spring.

- If the spring is connected to the bar, look for a pivot that moves the spring. Lubricate the pivot and reconnect the base plate.

Now, your reverse button should work. If it still does not work, contact the dealership.

Problem Four: Bobbin Winder Slipping

When the bobbin winder is slipping, you will face issues such as uneven winding, loose bobbins, or bobbins that are not fully filled. This happens because the winder is not gripping the bobbin securely. Also, sometimes the shuttle hook may not turn.

Reason: Broken Bobbin Winder Spindle

The bobbin winder spindle gets broken or damaged that causes bobbin winder slipping

Solution: Replace the Spindle

Check the bobbin winder spindle at the top of the sewing machine. In the event that it is broken, you will have to replace it. Call in an expert to get that done.

Problem Five: Stuck in One Stitch

The machine may get stuck in one stitch despite turning the dial.

Reason: Thread Jammed Inside the Machine

The machine will get stuck in one stitch if there are threads jammed inside the machine.

Solution: Clean the Machine Thoroughly

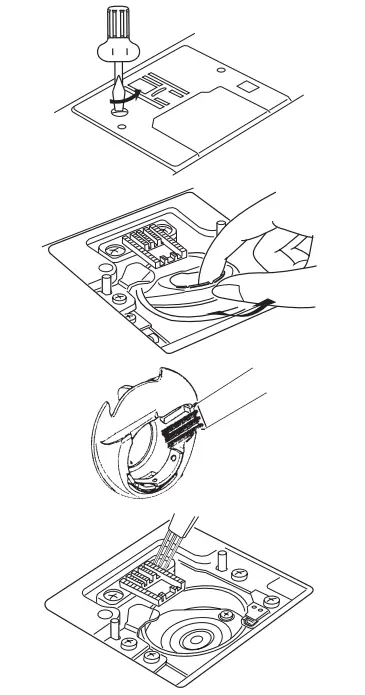

It’s best to conduct a thorough cleaning when this happens. Here is how you can do that-

- Turn off and unplug the sewing machine, then remove the presser foot and needle.

- To remove the needle plate, take out the screw on its left-hand side with a screwdriver.

- The bobbin must be removed along with the bobbin holder. It is necessary to lift up the bobbin holder in order to remove it.

- You will need to use a lint brush to clean your bobbin holder, and you will also need to use a soft, dry cloth to clean the feed dogs and hook race.

- To replace the bobbin holder, ensure that the triangle marks on the bobbin holder are aligned properly and position it such that the notch fits next to the stopper in the hook race.

- In the bobbin holder, place the bobbin.

- You will need to attach the needle plate, presser foot, and needle to the machine.

Problem Six: Feed Dogs Not Working

Sometimes the feed dogs may not work correctly or at all.

Reason: Broken Feed Dogs

Your feed dogs are not working, either because the feed dog or the lever that raises it is broken.

Solution: Replace the Feed Dogs

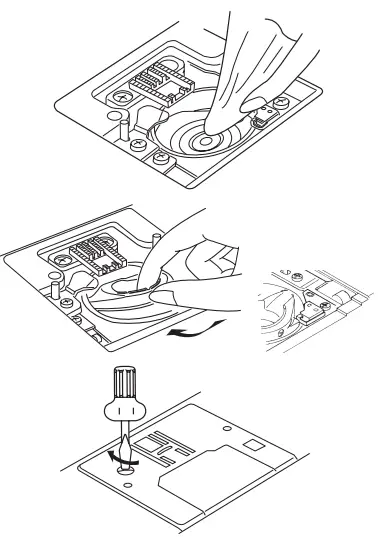

You will have to take out the feed dog and check it for damage. Replace it if it is. Follow the below process for checking-

- Turn off the machine, unplug it, and remove the presser foot and needle.

- You can remove the needle plate by loosening and removing the screw on the left side.

- It should now be possible for you to see the feed dogs. Check if they are broken or damaged. If it is, contact the dealer for replacement.

Problem Seven: Top Thread Tangles Around Take Up Lever

Although this is a very common issue, sewists seem to struggle with it. That’s because when the top thread becomes tangled around the take-up lever, it causes the machine to jam and the thread to break.

Reasons:

- Wrong orientation of the thread spool.

- Using incorrect needle or thread.

- Incorrect tension of the thread.

- Rough spots in the foot plate.

- Dirty tension discs.

Solutions:

- Try using a different spool of thread.

- Check the orientation of the thread spool. Turning the spool around may help. Then the thread will come off from the opposite end.

- Make sure the needle you use matches the thread and the job. Using the wrong needle can cause problems with the thread.

- Make sure that the thread is not excessively tight. Loosen it if it is.

- Check for any burrs or rough spots around the hole in the foot plate. Please be sure to clean the thread if it catches on these.

- Check the tension discs for any burrs or debris. It’s possible to remove and clean them with alcohol and a bit of clear machine oil. Alternatively, you can use pipe cleaners with alcohol to clean between the discs.

Problem Eight: Bobbin Casing Keeps Popping Up

While sewing, the bobbin casing my pop up. This will prevent you from sewing, as the thread will get jammed.

Reason: Dirty Bobbin Holder

This problem may arise if the bobbin holders don’t get cleaned often enough. That means, it may be clogged or dirty.

Solution: Clean the Bobbin Holder

To clean a bobbin holder, first turn it off and unplug it, then remove the presser foot and needle. After removing the needle plate, remove the bobbin and bobbin holder with a screwdriver. Clean the bobbin holder with a lint brush.

Problem Nine: Needle Gets Stuck in Clamp

While sewing, the needle may get stuck in the clamp. As a result, changing the needle is very difficult, and work is hampered.

Reason: Faulty Clamp

The clamp may be faulty and causing the needle to get stuck in clamp

Solution: Replace the Clamp

The needle clamp may need to be replaced. Contact your dealer for a replacement.

Problem Ten: Getting Loops Underneath Works

Reasons:

- Using the wrong needle size.

- The tension disc is not properly seated with the thread.

Solutions:

Check the needle chart mentioned above for correct needle sizing. Rethread the sewing machine if it’s not seated correctly.

Janome HD 3000 Maintenance

Even if you are using the best sewing machine in the world, if you do not maintain it the way you should, you will inevitably face problems. The following tips will help you take care of your Janome HD 3000.

- If you’re using a sewing machine for the first time, it’s recommended to place a piece of scrap fabric under the presser foot. Run the machine without any thread for a few minutes to ensure everything is working correctly before starting your project.

- If the sewing machine is damaged, dysfunctional, or has been dropped, do not use it.

- To ensure proper air flow and prevent blockage, it’s crucial to keep the ventilation openings of the sewing machine and foot controller free from lint, dust, and loose cloth. Be sure to clean these areas regularly to maintain the machine’s functionality.

- Whenever you are using aerosol products or administering oxygen in an area where sewing machines are being operated, be sure not to operate the sewing machine.

- The correct needle plate must always be used, and bent needles must not be used, as this can result in the needle breaking, due to the bend in the needle.

- While stitching, avoid pulling or pushing the fabric, as this can deflect the needle and cause it to break.

- Turn off the sewing machine when adjusting the needle area, such as when threading the needle, changing the needle or presser foot, or threading the bobbin.

- Whenever you remove covers, lubricate, or make any other adjustments to a sewing machine, unplug it from the electrical outlet first.

- It is recommended that the main switch be switched off or that the sewing machine be unplugged from the socket-outlet when leaving it unattended.

- Avoid placing any objects on the foot control, as they could cause the machine to start accidentally or damage the control.

Frequently Asked Questions (FAQs):

Is the Janome HD3000 worth it?

Yes, the Janome HD3000 is worth it. It is a popular and highly rated sewing machine with many advanced features, making it a good investment for serious sewists. It also comes with a durable metal construction, making it a reliable and long-lasting machine.

How fast is Janome HD3000?

The Janome HD3000 is a fast and efficient sewing machine, capable of sewing up to 860 stitches per minute. This makes it a great choice for large projects or for sewists who need to complete their work quickly and efficiently.

Does Janome HD 3000 need to be oiled?

No, the Janome HD 3000 does not need to be oiled. After each use, the user only needs to clean the hook race, feed dogs, and remove the bobbin from the machine.

Conclusion

While the Janome HD-3000 sewing machine is generally well-regarded for its many advanced features, users may experience issues from time to time. Common Janome HD3000 problems include such things as tension problems, needle breakage, and jamming.

The machine can, however, be kept in good working order for years to come with regular maintenance. With proper care and attention, the Janome HD-3000 can be a reliable and efficient tool for sewists of all levels.