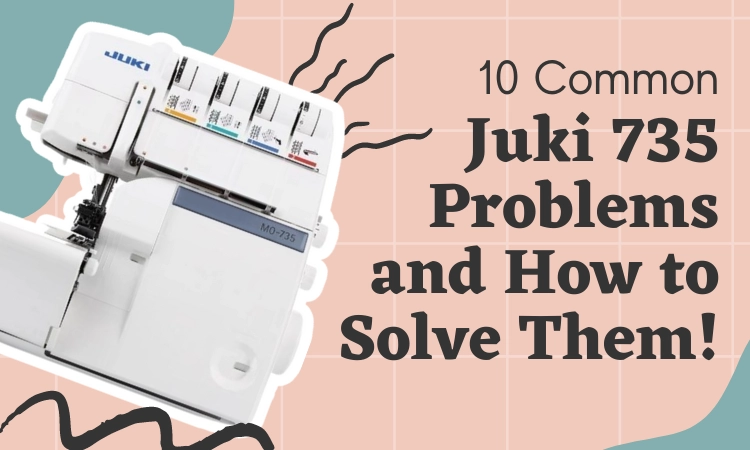

10 Common Juki 735 Problems and How to Solve Them!

Juki 735 is one of the most popular sewing machines produced by Juki. However, that doesn’t mean you don’t have to face problems with this sewing machine from time to time.

So, how to fix Juki 735 problems?

Most Juki 735 problems will be solved if you properly install the threads & needles and the needles are in good condition. Make sure the security covers are closed and the differential feed is in the right settings. Reducing or increasing the seam width and foot pressure can also fix some of the Juki 735 problems.

Only this much information is not enough to solve a specific Juki 735 problem. So, keep reading and find out every problem with proper reasons and solutions.

Juki 735 Problems: Reason & Solution

There are several problems you may often face with the Juki 735 sewing machine. Here are those problems with proper reasons and solutions.

| Problem | Reason | Solution |

| The machine does not sew | Open cloth plate or looper coverMachine isn’t plugged inMain switch is off | CLose the security coversPlug in the machineTurn on the main switch |

| Machine feeds fabric unevenly | Wrong differential feed adjustmentWrongly positioned lower or upper knifeBlunt knives | Adjust the differential feed correctlyChange the knives and position them correctly |

| Needle breaks | Wrong needle adjustmentNeedle is blunt or bentPulling the fabric while sewing | Replace the needle and install it correctly. Don’t pull the fabric while sewing. |

| Thread breaks | Thread tension is excessively tightImproper needle installationthe Wrong needle | Reduce the thread tensionInstall the right needle properly. |

| Skipped stitches | Wrong or blunt needle Foot pressure padel is too light | Install the right needle in the correct way.Increase the foot pedal pressure |

| Seams flute or wave | Pulling the fabric while sewingFoot pressure padel is too tightIncorrect setting of the differential feed | Don’t pull the fabric while sewingReduce the foot pedal pressureChange the differential feed to the N-2 setting |

| Seams pucker | Needle thread tension is excessively tightDifferential feed setting is improper | Decrease thread tensionChange the differential feed to the 0.7 – N setting. |

| Fabric edges curl | Too much fabric in the stitchTight fabric tensionStitch selection lever is kept on the roll hem | Lower the fabric widthReduce the fabric tensionSelection lever is in overlock settings |

| Poor stitch formation | Thread is not properly seated between the tension disc. Thread gets caughtThreading is improper | Make sure the thread is properly seatedRe-thread the machine |

| Loose Thread loops | Fabric width in the stitch is too little | Increase the seam width |

Problem 1: The machine does not sew

The most common problem the user faces with Juki 735 is the machine doesn’t sew.

Reason:

The reason behind the Juki 735 machine, not sewing, is that you forgot to close the cloth plate or looper cover. Also, if the sewing machine is not plugged in or the main switch is off, the Juki 735 won’t sew. In the worst-case scenario, the machine might be faulty.

Solution:

- Plug the polarized plug of the foot control in the main socket. As the Juki 735 sewing machine plug is polarized, it is recommended to use a polarized main socket. Otherwise, there is a chance of getting an electric shock..

- Check if the main power of the Juki 735 is turned on. you will find this power switch on the front side of the machine near the handwheel side. You have to press the (I) side to turn the switch On.

- Make sure the looper cover is closed. If this looper cover is not closed, the Juki 735 machine won’t sew. This clover is on the front side of the machine. Push the cover-up and gently press it to the right. The cover will be automatically engaged by the machine.

- Ensure the cloth plate cover is closed as well. This is on the needle side of the machine. To close the cover, push it to the right side.

If none of this works, you have to take the Juki 735 machine to the dealer. They will either repair it or replace it based on the problem.

Problem 2: The Machine Feeds Fabric Unevenly

In Juki 735, you may sometimes notice that the fabric you are sewing isn’t evenly fed by the machine.

Reason:

If you adjust the differential feed in the wrong way, you will see the fabric feeding in an uneven manner. Also, too low foot pressure and a blunt or wrongly positioned lower or upper knife can cause this problem.

Solution:

- Turn the differential feed dial of your Juki sewing machine left or right and check if the cloth is fed evenly.

- Give pressure to the foot pedal according to the thickness and stiffness of the cloth. Thicker or stiffer clothes require more pressure. So, if the cloth is fed unevenly, put more pressure on the padel and see if that works.

- Visibly check the upper and lower knife. Make sure the knives are properly adjusted and the tip is not broken. If the upper or moving knife is found broken or blunt, you have to contact your sewing machine dealer and have it changed. If the lower knife is blunt or broken, you can replace it on your own in the following way.

Step 1: Turn Off the sewing machine and pull the power plug off.

Step 2: Raise the needles to the fullest by turning the handwheel towards you. Make sure the handwheel’s matching mark is aligned with the side cover mark.

Step 3: Raise the moving or upper knife.

Step 4: with a compatible screwdriver loosen the lower knife’s setscrew and remove the knife.

Step 5: Take a new knife and feed it to the knife groove. Tighten it with the screwdriver.

The uneven cloth feeding problem should be gone by now.

Problem 3: Needle breaks

The needle keeps breaking while sewing can be another annoying problem in the Juki 735.

Reason:

This problem occurs when the needle is wrongly inserted or it is bent or blunt. Also, if you pull the fabric while sewing, the needle will break.

Solution:

- Visibly check if the needle is bent or if the needle is blunt. If the needle is found damaged, you have to replace the needle. Replacing the needle is almost similar in all the machines. For example, replacing the needle of the Brother machine and the Juki Sewing machine requires an almost similar procedure.

- Make sure the needle placement is correct. The needle should be all the way into the needle clamp and the flat part of the needle should be on the back.

- Make sure not to pull the fabric while sewing. Use both hands to guide the cloth towards the needle.

Problem 4: Thread breaks

Sometimes in Juki 735, the thread can keep breaking. It is not only annoying but also makes the stitches look unfinished.

Reason:

If the thread tension is excessively tight or if you didn’t thread the machine properly, you can face this problem. Also, improper needle installation and the use of the wrong needle can cause this issue.

Solution:

- Reduce the thread tension by turning the tension dial downwards. The ideal tension should be between 3 to 5 for most clothes. But some special threads like wool and nylon may require lesser tension.

- You have to make sure the machine is threaded properly. The following video will help you with that.

- Make sure the needle is properly installed in the needle groove.

- Use only the 130/705H needle system for your Juki 735.

Problem 5: Skipped Stitches

Sometimes, you may notice that your Juki 735 machine is skipping stitches. This problem can also make the stitches appear unfinished.

Reason:

When you use the wrong or blunt needle you can face problems. Moreover, pressing the foot pressure padel too lightly can cause this.

Solution:

- Check and if necessary replace the needle and make sure to use 130/705H needle only.

- Increase the pressure of the foot pedal.

Problem 6: Seams flute or wave

In Juki 735, the seams can sometimes be wavy or fluted. This problem can be more frequent in jersey knit fabrics as sewing with jersey knit can be complicated anyway.

Reason:

If you pull the fabric while sewing, the seam can be wavy or flute. Other reasons for this problem can be pressing the foot pressure too tightly or incorrect setting of the differential feed.

Solution:

- Make sure you guide the fabric into the needle carefully with both hands.

- Press the foot pedal with reduced pressure.

- You have to change the differential feed to the N-2 setting.

Problem 7: Seams pucker

Many Juki 735 users complain about seams puckering or the seams being gathered in one place of the fabric.

Reason:

If the needle thread tension is excessively tight or the differential feed setting is improper, you can face this problem.

Solution:

- Rotate the needle thread tension dial downwards and decrease the thread tension.

- Change the differential feed to the 0.7 – N setting.

Problem 8: Fabric Edges Curl

Juki 735 can sometimes curl the edges of your fabric. As a result, the fabric gets bumpy while sewing and the garment gets ruined.

Also, while sewing Nylon fabric or other sensitive fabric like that, you need to provide special attention anyway. This curling edge problem can damage these sensitive fabrics more quickly.

Reason:

This problem can occur when there is too much fabric in the stitch. Also tight fabric tension and if the stitch selection lever is kept on the roll hem you can face this problem.

Solution:

- You have to decrease the cutting width of the fabric in the following way.

Step 1: Turn the sewing machine Off and disconnect the power plug.

Step 2: Raise the moving or upper knife.

Step 3: Rotate the width adjustment dial and reduce the seam width and check if the curling problem is gone.

- Rotate the tension dial downward and reduce the thread tension.

- Check and make sure the selection lever is in overlock settings.

Problem 9: Poor Stitch Formation

You might sometimes notice the stitch or seam formation of your fabric is not aligned and correct.

Reason:

Bad stitch formation happens when the thread is not properly seated between the tension disc. Also, if the thread gets caught in the machine and the threading is improper, you may face this.

Solution:

- Check the tension discs and make sure the thread is properly seated between them. If not, remove the thread and hold it with both hands. Install the thread into the discs from the back to the front following the arrow direction. And pull the thread gently making sure it doesn’t get removed from the discs.

- Raise the pressure foot pedal, gently pull the thread and perform rethreading.

Problem 10: Loose Thread loops

Another problem that Juki 735 users sometimes face is getting loose thread loops in the fabric.

Reason:

If the fabric width in the stitch is too little, you may face this problem.

Solution:

Increase the seam width and the problem should be gone.

Frequently Asked Questions (FAQs):

What Does Correct Serger Tension Look Like?

In the correct serger tension, the looper stitch will meet the edge of your fabric properly. If the serger tension is incorrect, the looper stitch will be too distant from your fabric’s edge or the knife will cut excessive fabric.

Do Juki sewing machines need to be oiled?

Yes, the Juki machine needs to be oiled after every 4-5 hours of sewing. You have to put only a tiny drop of oil in every oiling place of the machine.

Conclusion

Here goes all the Juki 735 problems with possible reasons and proper solutions. Whether you are planning on buying a Juki 735 or want to repair your existing one, this article should help.

For now, I have to bid farewell. Have a great day!