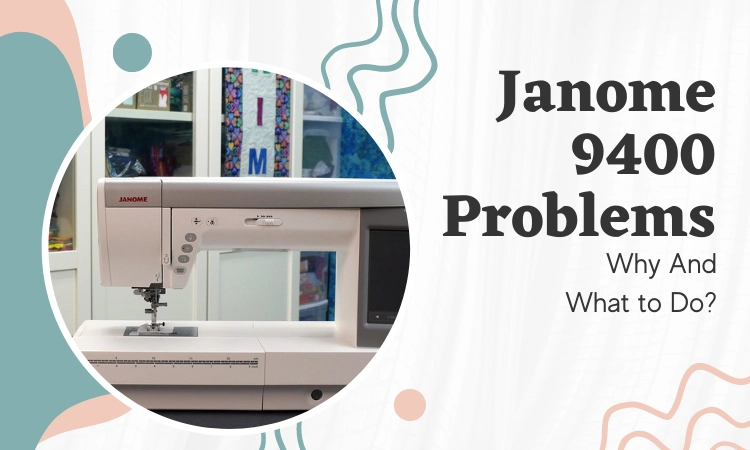

Janome 9400 Problems: Why And What to DO?

Janome 9400 problems include unsmooth fabric feeding, improper button hole sewing, machine noise, auto thread cutter failure and machine not running. Other common problems are pattern selection not possible, needle thread on the wrong side, machine halting, bad foot control and skipped stitches.

Still confused about Janome 9400 problems? These problems can often be a bit tricky to solve. Patiently follow these steps in order to solve your Janome 9400 problems.

Janome 9400 Problems: Quick Fix

Just like i did for Janome hd-3000 problems, I will address some common Janome 9400 problems and how to solve them in detail. But first, let’s have a quick glance:

| Problems | Reasons | Solutions |

| Unsmooth Fabric Feeding | 1. Lint in feed dog 2. Too fine stitch 3. Feed dog not raised after drop feed sewing | 1. Clean out the feed dog 2. Make a longer stitch 3. Raise the feed dog |

| Improper Button Hole Sewing | 1. Unsuitable stitch density 2. Interfacing not being used 3. Buttonhole lever is not lowered | 1. Adjust stitch density depending on the fabric 2. Use an interfacing. 3.Raise the buttonhole lever |

| Additional Noise | 1. Lint in hook race 2. Lint in bobbin holder 3. Thread tangled in the hook race | 1. Clean out the lint from the bobbin holder and hook race. 2. Untangle thread from the hook race |

| Auto Thread Cutter Failing | 1. Thread tangled in cutter 2. Thick thread | 1. Untangle any tangled thread from the cutter. 2. Switch to a thinner thread. |

| Machine Not Running | 1. Thread tangled in hook race 2. Using start/stop button for ordinary sewing while foot control is connected. | 1. Untangle any tangled thread from the hook race. 2. Disconnect the food control |

| Pattern Selection Not Possible | 1. The key position is not aligned correctly. 2. Needle plate for straight stitching or the professional needle plate is connected. 3. Dual feed key is on4. Twin needle key is on | 1. Align the key position. 2. Connect the correct needle plate 3. Turn off the dual key and the twin key. |

| Needle Thread on Wrong Side | Unbalanced thread tension | Balance the thread tension |

| Machine Halting | Overload | Remove tangled threads from the hook race, take-up lever and auto thread cutter. Restart the machine. |

| Food Control out of Order | Bad foot control | Contact service center |

| Skipped Stitches | 1. Incorrect needle insertion 2. Bent needle 3. Blunt needle 4. Improper needle threading 5. Bad needle | 1. Use good needles. 2. Threads and needles of appropriate size with the right fabric, as recommended by Janome. |

Still confused about how to fix your Janome 9400? Don’t you worry. Our detailed sections below will have all the answers you’re looking for.

Janome 9400 Problems: Detailed Fix

Still confused about Janome 9400 problems? Do not worry, because we have got you covered. Here are the fixes of some of the most common Janome 9400 problems in details.

Problem 1: Unsmooth Fabric Feeding

Your fabric feeding in Janome 9400 is unsmooth because your feed dog is filled up with lint. Other reasons that can cause problems with your fabric feeding are your feed dog remaining lowered and stitches that are too fine. This problem can be easily addressed.

Reason 1: Feed Dog is Packed with Lint

If there’s any lint stuck in the feed dog, fabric feeding won’t be smooth.

Solution: Clean Out The Feed Dog

To clean out the feed dog, follow this method:

- Turn off and unplug the machine.

- Unscrew and remove the needle plate.

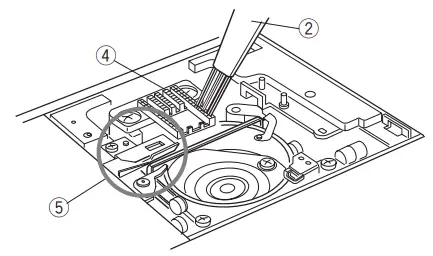

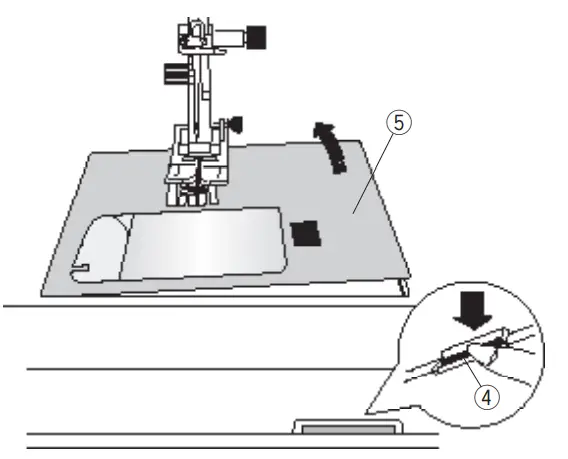

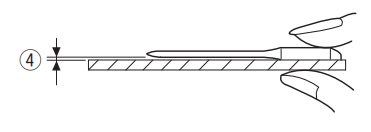

- Use a lint brush or a clean cloth to clean out the feed dog. Use alcohol if necessary. This is a picture of the feed dog pointed out as number 4:

- Reattach the needle plate. Make sure it is properly aligned and screwed securely.

Reason 2: Stitch too fine

Selecting stitches that are too fine can cause problem with fabric feeding.

Solution: Use a longer stitch length.

You may use a longer stitch to reduce the stitches made per inch of fabric. This would reduce the tension on the fabric, making the fabric move much more smoothly.

Reason 3: Feed dog not raised after drop feed sewing

You may have forgotten to raise the feed dog, which could in turn cause this problem.

Solution: Raise your feed dog.

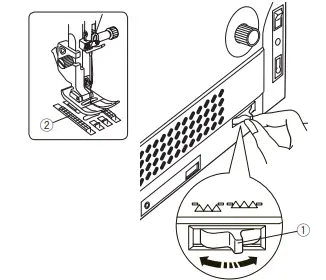

To bring the feed dog back to the upper position, shift the drop feed lever away from you. This is an illustration of the drop feed lever shown as number 1 and feed dog as number 2:

Problem 2: Improper Button hole Sewing

Your button holes are not sewing correctly with Janome 9400 because you picked the wrong stitch density. Not applying interfacing could also cause this issue. The solution to this problem is very easy.

Reason 1: Unsuitable stitch density

Not choosing the correct stitch density could be the cause of the issue.

Solution: Adjust the stitch density

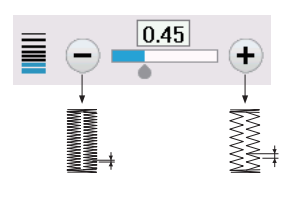

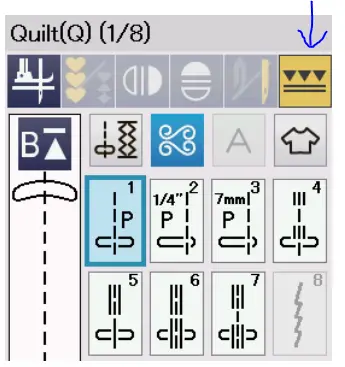

The stitch density may not be suitable for the fabric you are using. Try changing the stitch density to see which value is better for you. This is an illustration of the stitch density changing panel for Janome 9400:

You can adjust the stitch density by pressing on the ‘+’ sign to lower it and ‘-’ sign to increase it.

Reason 2: Interfacing not being used

Not applying interfacing when making button holes can cause the sewing to go wrong.

Solution: Apply interfacing

Use an interfacing when creating button holes. Using an interfacing can help stabilize the fabric. So the fabric does not stretch or distort when sewing the button hole.

Problem 3: Additional Noise

Your Janome 9400 sewing machine is making additional noise because there is lint in the hook race or the bobbin holder. Thread getting tangled with the hook race can also be the cause of this noise. It is, however, normal to hear a light hum. This sound is made by the electric motors.

Reason 1: Lint in hook race

Lint in your hook race can cause noise.

Solution: clean out your hook race.

Clean out the lint from the hook race following these steps:

- Turn off the sewing machine and unplug it.

- Unscrew and remove the needle plate.

- Remove the needle and the presser foot.

- Clean the hook race with a lint brush or a soft cloth.

- Reattach the needle and presser foot.

- Put back the needle plate and screw in the screws.

Reason 2: Lint in bobbin holder

Lint can get stuck in your bobbin holder and make noise.

Solution: clean out your bobbin holder.

To clean out the lint in the bobbin holder:

- Follow steps 1 to 3 of the process of cleaning out your hook race.

- Take out the bobbin and the bobbin holder.

- Use a clean cloth or lint brush to remove lint from the bobbin.

- Put back the bobbin and the bobbin holder in its original place.

- Follow steps 5 and 6 of the process of cleaning out your hook race.

Reason 3: Thread tangled in the hook race

Sometimes your thread can get tangled with the hook race when sewing.

Solution: Untangle the thread.

To untangle the thread from the hook race, follow the steps mentioned in the process of cleaning out your hook race. If untangling the tread is too difficult, you can cut off the tangled thread with a pair of scissors.

Problem 4: Auto Thread Cutter Failing

The auto thread cutter of your Janome 9400 can fail because of your thread being too thick or thread getting tangled with cutter.

Reason 1: Thick thread

Your thread cutter may fail to cut your thread if it is too thick.

Solution: Use the thread cutter on the face plate.

Usually pressing the thread cutter button after finishing sewing will cut the threads for you. But if the thread you are using is too thick or specialized, you need to use the thread cutter on the face plate

To use the thread cutter on the face plate, follow these steps:

- Remove the fabric and draw it to the back.

- Pull the thread up and put it between the faceplate and the thread cutter.

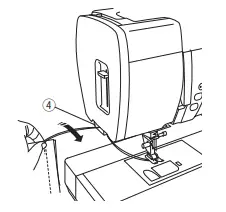

- Then pull on the thread to cut it off. This is an illustration of the process where the thread cutter is labeled as 4:

Reason 2: Thread tangled in cutter

The thread has gotten tangled with the automatic thread cutter.

Solution: Untangle the thread

If the thread gets tangled with the thread cutter when sewing, the cutter will not work. Simply untangle the threads to use the auto cutter.

Problem 5: Machine Not Running

Your Janome 9400 machine is not running because the thread got tangled in the hook race. Pressing the start/stop button while having the foot control connected can also prevent the machine from running. This is a very common problem for Janome 9400 sewing machines.

Reason 1: Thread tangled in hook race

The thread has gotten tangled with the hook race of your sewing machine.

Solution: Untangle the thread.

Follow the steps mentioned here to untangle the thread from the hook race.

Reason 2: Using start/stop button for ordinary sewing while foot control is connected.

If your foot control is connect to the machine, then pressing the start/stop button will not make the machine run.

Solution: Remove foot controller.

Disconnect the foot controller, as the start/stop button does not function with the foot controller attached.

Problem 6: Pattern Selection Not Possible

Pattern selection is not possible in your Janome 9400 because either the dual feed key or the twin needle key is on. Also if the key position is incorrectly aligned, or the wrong needle plate is inserted this issue will occur.

Reason 1: The key position is not aligned correctly

Wrong alignment of the keys can make selecting pattern on your sewing machine not possible.

Solution: Calibrate your display

Your pattern selection may not be working because your key positions are not correctly aligned. To align the keys, you have to calibrate the display. To calibrate the display, follow these steps.

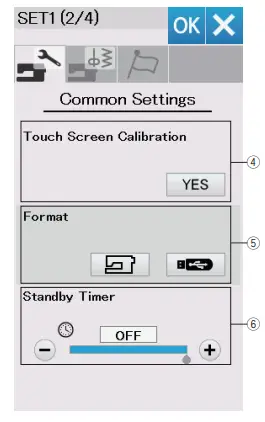

01. Press the set mode key to enter machine settings.

02. Press the arrow key labeled in this picture as item 6 to go to the next page:

03. Press on the YES button shown here in this picture as item 4:

04. Press the ‘+’ sign that shows up on the display. The sign will show up multiple times throughout the calibration period. Press it every time.

05. After pressing the last ‘+’ sign, the screen will display END. The calibration window will automatically close after this.

06. Now that the touch screen display of your Janome 9400 is fully calibrated, check if the pattern selection keys are now working.

Reason 2: Needle plate for straight stitching or the professional needle plate is connected.

If you are using the wrong needle late your key patterns will be grayed out on the display.

Solution: Replace the needle late

If you have the straight stitch or the professional grade plate attached to your Janome 9400, some of the patterns will be unavailable. Only patterns that are compatible with the needle plate you have currently attached will be accessible.

To replace the professional grade or straight stitching needle plate you have currently installed:

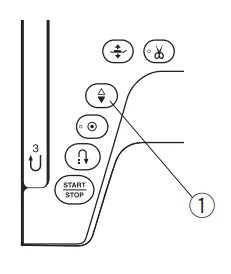

01. Raise the needle first, by pressing the needle up/down button as shown here by 1:

02. After that, press the lockout key as shown in this picture of the display by 2:

03. Then press the presser foot lifter button to lift the presser foot as shown in this picture by the number 3:

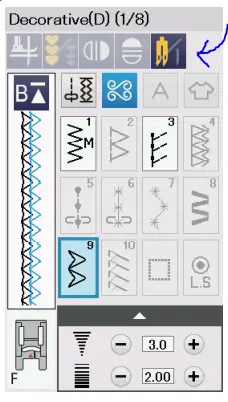

04. Slide the extension plate to the left to remove. Also, press the needle plate release lever as shown here numbered 4:

05. The needle plate will then snap off. Remove the needle plate, shown in the above picture as number 5.

06. A warning sign will appear on the screen, telling you that the needle plate has been removed

07. Place the new needle plate on the spot of the old plate on the machine and push it down. To access the pattern keys, the new plate should not be a professional grade plate or a straight stitch plate.

08. The warning sign will go away after the new plate is connected.

09. Now you can access the pattern selection keys from the display.

Reason 3: Dual feed key is on

Having the dual feed key on will prevent you from selecting certain patterns.

Solution: turn off the dual feed key

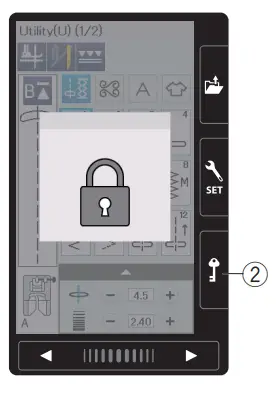

If the dual feed key is on, the patterns not usable by dual feed sewing will be grayed out. Only patterns U1 to U5 and Q1 to Q7 will be accessible if this key is on. Turn off the dual feed key to access other patterns. Turn off the dual feed key by pressing the button marked in this picture:

Reason 4: Twin needle key is on

Having the twin needle key on will also gray out certain stitch patterns.

Solution: Turn off the twin needle key

If the twin needle key is on, the patterns which are not suitable with twin needles will be grayed out. These include button holes, specialty stitches and monograms.

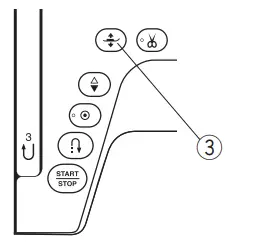

To turn off the twin needle key, press the button shown here:

Problem 7: Needle Thread on Wrong Side

This is a frustrating problem that sometimes occurs when using the Jenome 9400.

Reason: Unbalanced thread tension

Unbalanced thread tension can cause the needle thread to be on the wrong side.

Solution : Adjust thread tension

Having unbalanced thread tension can cause the needle thread to be on the wrong side when stitching. This happens when the stitch width value is larger than 7. You may fine tune the thread tension as the following:

01. To tune the balance on your threading, go to the Utility menu which houses the utility stitches, specialty stitches and buttonhole stitches. To do that, press this button:

02. Go to the settings bar by pressing the location labeled here as 1:

02. Press the ‘+’ sign if the tension is too loose, or press the ‘-’ sign if tension is too high.

03. Balance the tension on the needle thread until the needle thread is no longer on the wrong side.

Problem 8: Machine Halting

Sometimes your Janome 9400 can halt while stitching and stop working. This is a normal issue.

Reason: Overload

Overloading your machine can cause it to halt when sewing.

Solution: Untangle the threads from the machine

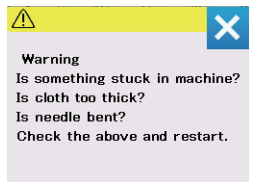

Sometimes your Janome 9400 can halt due to overload and give you a warning as shown here:

In that case, remove the tangled threads from the hook race, the automatic cutter and the take up lever. Then wait for 15 seconds to restart. The machine will now work again.

Problem 9: Food Control out of Order

If your foot control is malfunctioning or not working at all, take it to a Janome service center or to your dealer. You can not repair a bad foot control by yourself without specialized knowledge.

Reason: Bad foot control

Your foot control is bad.

Solution: Seek professional help

A bad foot control will give you this warning:

If this happens, contact the service center. A bad foot control can not be repaired without professional help.

Problem 10: Skipped Stitches

Your Janome 9400 is skipping stitches because the needle is bent or blunt, or you inserted the needle incorrectly. Using the wrong needle will also cause this issue.

Reason 1: Bent or blunt needle

Your needle could be bent or has gotten blunt and can not penetrate the fabric correctly.

Solution: Replace the needle

If you are getting skipped stitches due to bent or blunt needles, you need to replace them. Follow the steps below to replace your bad needle with a new needle:

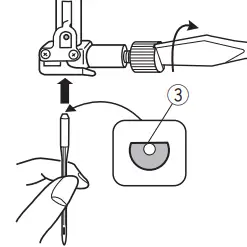

01. Check if the new needle is straight by putting it on a flat surface, such as the needle plate. The needle is straight If the gap between the surface and the needle is consistent as shown here:

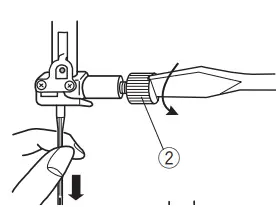

02. Raise the needle and lock it as shown in the first 2 steps of the needle plate changing process.

03. Loosen the needle clamp screw by rotating it counterclockwise using a screwdriver as shown here:

04. Pull the needle out of the clamp.

05. Put the new needle into the clamp with the rear end inside and then screw in the needle clamp screw as shown here:

Reason 2: Incorrect needle insertion

You may have inserted the needle into the needle clamp in a wrong way.

Solution: Reinsert the needle

If the needle is incorrectly inserted, for example if the clamp screw is loose, you need to reinsert it and screw it correctly. Follow the steps stated above for replacing bad needles to solve this problem.

Reason 3: Improper needle or thread

There are different types of threads like v69 and v92 threads and they’re not always interchangeable. This is applicable for needles as well. So, improper needle or thread can cause skipped stitches.

Solution:

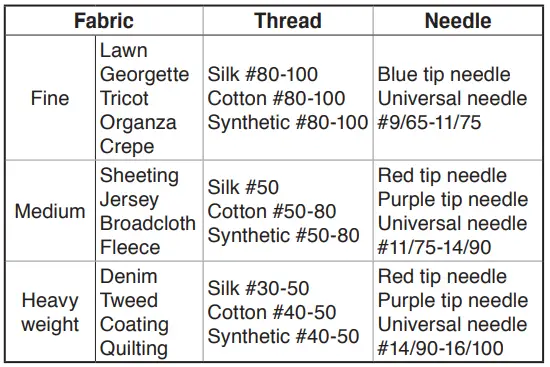

Replace the needle or the thread with the Janome recommended sized ones. Here is a table from Janome showing what size threads to use with which needles and for which fabrics:

The needle case provided by Janome with your Janome 9400 sewing machine contain the following needles:

- 1 twin needle

- 1 purple needle

- 1 red needle

- 2 blue needles

So, that was all for Janome 9400 problems. Now, you might be thinking if you should consider Juki instead of Janome. I’ve written a detailed comparison on Juki vs Janome for you to take a look at before purchacing your next sewing machine.

Frequently Asked Questions (FAQs):

Do Janome sewing machines need to be oiled?

Yes, Janome sewing machines need to be oiled. They need a tiny bit of oil on the wick that sits under the bobbin case. Other parts of Janome sewing machines need to be lubricated by the dealer or Janomer service center. Some more parts of these machines can be lubricated by the consumer. But due to electronics and computers inside, it is best for the dealer to lubricate it.

Which is better, Brother or Janome?

Brother machines are better than Janome in terms of affordability. On the other hand, higher end sewing machines of Janome are better than those of Brother. Both manufacturers, however, are highly reputed and make some of the best sewing machines. Machines from both companies come with a range of great features.

Is Janome 9400 high shank?

Yes, Janome 9400 is a high shank machine. It’s because the distance between the base of the foot and center of the presser foot thumb screw is more than 1 inch. Because of this reason, you can use the Janome 9400 for a wide range of applications. Janome 9400 is better at thick and heavy materials like leather compared to low shank machines. But it is quite big in size.

Conclusion

I hope this article managed to satisfy your questions about Janome 9400 problems. These problems can often be very frustrating for the user. Janome 9400 is a very good, but quite a sophisticated machine. For any future problem, feel free to consult this article again.

That is it for today. All the best and goodbye!